The increasing complexity and competitive nature of various industries demand a top-notch operational efficiency that many small and medium-sized businesses (SMBs) are striving to achieve. One of the most promising avenues for improvement lies in the integration of artificial intelligence (AI) workflows into daily operations. For businesses focused on sectors such as manufacturing, logistics, and energy, understanding how to leverage AI-driven automation strategies can significantly enhance decision-making processes, boost productivity, and ultimately improve the bottom line.

At the heart of enhancing operational efficiency through AI lies the ability to analyze vast quantities of data in real time. Many SMBs still engage in traditional methods for data collection and processing, which not only slow down operations but also increase the potential for human error. By adopting AI systems that utilize machine learning algorithms, businesses can rapidly analyze operational parameters and variables, thus informing better strategic decisions. For instance, a manufacturing firm can implement AI algorithms that analyze production line data to predict machine failures before they occur. This predictive maintenance approach can reduce downtime, streamline workflows, and enhance overall productivity.

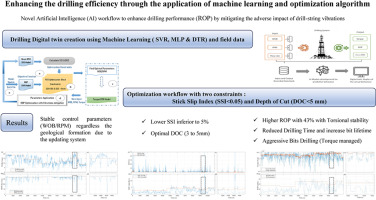

A compelling example of how AI can optimize tasks is seen in drilling efficiency, particularly within the energy sector. Recent studies have shown that leveraging machine learning techniques can greatly enhance drilling operations. The integration of multiple supervised machine learning algorithms, such as Multi-Layer Perceptron (MLP), Support Vector Regression (SVR), and Regression Decision Tree (DTR), allows for the creation of robust models. These models can be used to simulate various drilling parameters, such as bit rotation and rate of penetration, ultimately forming a digital twin of the drilling system. By employing these advanced models, companies can gain valuable insights into their drilling operations, pinpoint inefficiencies, and make real-time adjustments.

Furthermore, these AI systems can categorize specific issues such as torsional vibrations that adversely affect drilling performance. By integrating optimization techniques like Particle Swarm Optimization (PSO), businesses can finely tune parameters such as weight on bit (WOB) and rotation per minute (RPM). When optimized correctly, companies can see significant improvements in their operations. For example, simulations have demonstrated that companies applying optimized drilling parameters experienced a remarkable 43% increase in rate of penetration and improved torsional stability. By reducing the time spent in changing drill bits—from 66 hours down to 31 hours—companies not only save on operational costs but also complete projects more quickly, thus capturing more revenue.

Integrating AI-driven workflows is not just a technical upgrade; it represents a cultural shift that many SMB leaders should be aware of as they transition their teams into these new operational models. Embracing automation and AI means fostering a workplace environment that values data-driven decision-making. Leaders must ensure training and development are part of this transition, equipping employees with the necessary skills to interpret and act on insights yielded by these advanced technologies. This holistic approach ensures that the benefits of AI are fully realized across all levels of the organization, from upper management to frontline employees.

From a return on investment (ROI) perspective, the initial costs of implementing AI workflows and machine learning algorithms may seem daunting. However, the potential savings and efficiency gains overwhelmingly justify the investment. For example, companies that have adopted similar approaches in drilling have shown significant reductions in both time and costs. The improved rate of penetration, along with decreased need for manual tasks and adjustments, enables firms to allocate resources more strategically, yielding better financial outcomes in the long run.

In essence, the integration of AI into business operations acts as a powerful catalyst for efficiency, productivity, and informed decision-making. The potential applications are extensive, from operational analytics and predictive maintenance to optimization of workflows across various sectors. For SMB leaders looking to stay ahead in increasingly competitive landscapes, a deliberate focus on adopting these technologies can lead to marked improvements in performance and profitability.

FlowMind AI Insight: Successfully navigating the complexities of AI integration requires a steadfast commitment to education and adaptation. As SMBs begin to leverage AI-driven workflows, the potential for operational growth and innovation is immense, setting the stage for increased efficiencies and a stronger competitive edge in the marketplace.

Original article: Read here

2023-09-01 05:55:00