In recent years, the landscape of industrial automation has taken significant strides forward, particularly with advancements in artificial intelligence (AI) and robotics. Companies like Intrinsic, a robotics software firm under Alphabet, have unveiled promising developments that could revolutionize how multiple industrial robots operate within shared environments. This innovation, driven by long-term research in partnership with Google DeepMind, which has been rebranded as Gemini Robotics, and University College London, highlights the potential for businesses to improve operational efficiency and reduce costs.

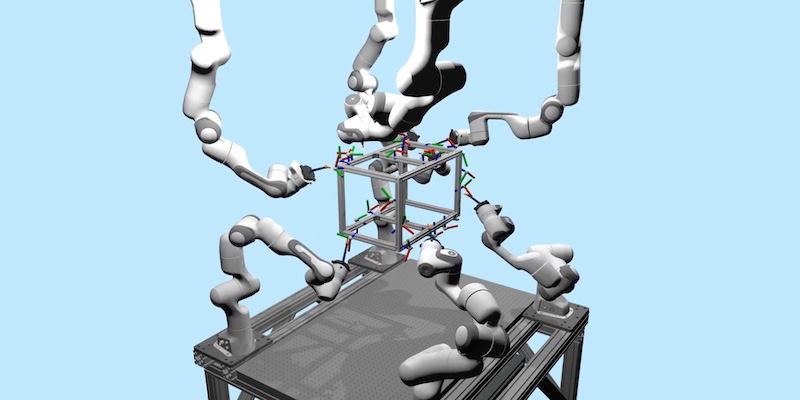

The core of this advancement lies in the ability of multiple robots to collaborate without colliding, a challenge that has long plagued traditional automation techniques. Historically, the programming process for multiple robots has been cumbersome, demanding manual coding for each robot’s movements. This approach is not only time-consuming and inflexible but also difficult to scale, especially as businesses seek to improve productivity. The new method introduced by Intrinsic promises to transform this paradigm by utilizing an AI model based on Graph Neural Networks (GNNs) combined with reinforcement learning.

For small and medium-sized businesses (SMBs) considering automation, utilizing AI tools like those from Intrinsic can be a game-changer, but it requires a thoughtful step-by-step approach. Here’s how SMBs can implement such advanced solutions effectively.

First, SMBs should begin by assessing their current workflows to identify tasks that can benefit from automation. Focus on repetitive and time-consuming processes such as inventory management, order processing, and quality control. Documenting these workflows will provide clarity on the needs that automation should address.

Next, exploring platforms like Make or Zapier can be beneficial. These tools enable businesses to integrate various applications seamlessly without requiring extensive coding expertise. For example, an SMB can connect its inventory management system to its order processing system. This would create a streamlined workflow where stock levels are automatically updated and orders processed without manual intervention, minimizing errors and freeing up staff for higher-value tasks.

The integration phase involves mapping out specific automation scenarios. Businesses will want to define how tasks will flow between different applications. In the context of robotics, consider the implications of adding multiple robots to your operations. As noted in Intrinsic’s research, their system can handle a “bundle of tasks,” allowing for autonomous motion sequence generation. Similarly, with automation platforms, SMBs can set triggers and actions that dictate howdifferent software systems interact. For instance, an event in one application, like a low inventory alert, could trigger an automated reordering process in another application.

Once automation scenarios are defined, it’s crucial to create a testing phase. Test runs allow SMBs to identify any potential roadblocks and adjust workflows before fully implementing the systems. If deploying robotic systems or advanced AI models, conducting simulations with synthetic data can be particularly useful to understand how these technologies will operate in real-world settings.

Monitoring performance is the next step. After implementation, businesses should measure the effectiveness of their automation efforts. Key performance indicators (KPIs) such as time savings, error rate reductions, and overall productivity improvements should be tracked. This not only helps in assessing the direct ROI of the automation project but also aids in identifying areas for further refinement. With Intrinsic’s AI model showing a potential 25% improvement over traditional methods, SMBs have strong benchmarks – and recognizing these metrics will allow them to determine their success more effectively.

However, alongside the opportunities presented by automation, risks must also be considered. Data privacy and cybersecurity are significant concerns when integrating automation and AI into operations. SMBs need to ensure they have robust security measures in place to protect their data and that of their customers. Moreover, as robots and AI systems become more integrated, reliance on technology may grow, necessitating contingency plans for equipment failure or unexpected outages to maintain business continuity.

In terms of ROI, the initial investments in time and resources to implement automation might seem daunting. However, businesses must understand that the long-term benefits far outweigh the short-term costs. Automation can lead to significant labor savings, enhanced accuracy, and improved turnaround times—all driving higher customer satisfaction and potentially increased sales. As highlighted by Intrinsic’s advancements, systems can be scalable; adding more robots or tasks typically results in even greater efficiencies.

Finally, continuous learning and adaptation should remain a focus for SMBs as they implement automation. As technologies evolve and new capabilities emerge, businesses must stay informed and be prepared to iterate on their processes. Future developments may soon allow automated systems to replan tasks in real-time, adjusting to unforeseen challenges, which is vital in fast-paced industries.

In light of these considerations, SMB leaders can position their organizations for success in the era of automation. By understanding the steps necessary for implementing AI tools and robotic technologies, businesses can streamline their workflows, enhance operational efficiency, and ultimately drive their growth.

FlowMind AI Insight: Embracing AI-driven automation is not just about keeping pace with technology; it’s about strategically transforming your operations for long-term advantages. With thoughtful implementation and continuous improvement, SMBs can unlock new levels of productivity and resilience in an increasingly competitive landscape.

Original article: Read here

2025-09-04 10:11:00